What is Time Study Analysis (TSA)?

Introduction

Techniques don’t just stay in their lane. What works in one area often finds its way into another. Take Time Study Analysis (TSA), for example. It’s not rocket science. It’s the simple idea that time is valuable. Or, as the saying goes, “Time is money.”

While plenty of experts have dived into time management over the years, one name stands out: Frederick Winslow Taylor, also known as the “father of scientific management.” He didn’t just study time, he made it a key part of how businesses run efficiently today.

In this post, we’re going to break down TSA – what it is, why it matters, and how businesses can use it to level up their operations. Let’s explore in-depth.

What is Time Study Analysis (TSA)?

To put it simply, time study is a technique used to observe how much time a specific task takes on the factory or production floor. Time measurement can be performed by an individual trained to do so, using a simple watch and a piece of paper to note down time measurements. However, since we live in modern times, this work is now done using specialized software that works with videos and cameras.

Time Study Analysis (TSA) is not limited to employees, it applies to machines as well. It takes into account time spent being actually productive and what is wasted. Using it, a benchmark can be established.

Take, for example, a coffee shop. The morning time is the rush hour. TSA can help track how long it takes a barista to make a cup of latte, all the way from taking the order to handing it over to the customer. If the milk frothing step slows the process down, it must be optimized. A new approach can be taken, like prepping the milk in advance.

This might only save a couple of seconds, but it adds up over a period of time and boosts the efficiency of the overall process. Naturally, this improves customer satisfaction as well.

Why Conduct Time Study Analysis?

Before you can improve efficiency, you need to know where you stand. That’s where TSA comes in. It helps you establish a baseline by revealing how work is currently being done and, more importantly, how efficiently (or inefficiently) it’s happening.

By conducting a time study analysis, your business can get the following benefits:

- Identify Inefficiencies: TSA reveals concerning areas and unnecessary tasks that slow your team down. You can’t solve what you can’t see, and TSA brings those issues to light.

- Set Accurate Benchmarks: By creating performance benchmarks, TSA makes sure there’s consistency, and it sets clear expectations for success.

- Improve Productivity: Once inefficiencies are addressed and goals are in place, your team can work smarter, not harder. This leads to real, measurable improvements.

Let’s go a little specific to truly grasp the value behind conducting time study analysis and answer why is time study analysis important for manufacturers.

Manufacturing is an expensive business, and every minute costs resources, both man and machine. Costs must be kept low and production high to yield the best results. Time study analysis helps manufacturers figure out where time is being wasted and how to improve efficiency. For example, it might show that workers are spending too much time looking for tools or adjusting machines, which slows down production. Once an issue like this is identified, it can be further rectified. In this particular example, simply organizing the workspace better should do the trick.

Moreover, TSA helps reduce downtime massively. Downtime occurs when a machine breaks down, usually due to a fault or because it requires maintenance. By studying how long a machine is able to perform at maximum capacity before showing signs of degradation, a maintenance schedule can be established to prevent failures, keeping production running at optimum pace.

What You Need for a Successful Time Study Analysis

Preparing and researching are crucial for a successful time study analysis. No matter if you’re managing a coffee shop or a manufacturing plant, the five key areas of TSA stay the same. They include:

Setting Clear Objectives

Before starting a TSA, establish what the goal is. Are you trying to reduce the time it takes to complete a task? Perhaps you want to identify areas where resources and time are being wasted. Having this clarity will assist with the task, and proper attention can be given to it. Based on your industry, see if any previous studies outline the industry standards. While not strictly applicable in all situations, it can act as a great reference point.

Qualified Observer

The person who will be conducting the TSA needs to be skilled in observing and recording the process accurately. Generally, in a plant, it tends to be an industrial engineer who understands the task that is being studied and can track each and every step without causing any interruptions. The observer is supposed to be neutral and unbiased so the data is reliable.

Suitable Tools and Equipment

Back in the day, time study was conducted using basic, rudimentary tools like a pen, pencil, paper, and a stopwatch. However, this method always left some margin for error due to the simple fact that it primarily depended on the abilities of the humans using them.

The way the technology has improved over the years, you no longer need to go manual. Tools such as time-tracking software and cameras have replaced the classics. These are far superior, as they can observe employees passively.

Employee Buy-in and Sample Size

Secretly monitoring employees isn’t just unethical but also counterproductive. Focus on transparency and collaboration. Start by holding a meeting to explain the process. Show your team how TSA can make their work lives better by reducing repetitive or unnecessary tasks. Building trust upfront paves the way for smoother implementation.

But transparency isn’t the only factor because accuracy matters too. Avoid skewed results by making sure there’s a balanced sample size. Analyzing only top performers or struggling employees creates a distorted picture. Instead, focus on average team members who reflect typical performance levels.

Selecting the Right Time Frame

Similar to choosing the right sample size and group, selecting the right time for conducting a time study is important to get a fair idea of the workflow within a production line. Production typically goes through both high-intensity and low-activity phases, but these are mere exceptions. It’s best to pick a time when things are moving at a general or average pace to make sure the study reflects normal operating conditions.

Avoid periods when external factors might skew the results, such as during training sessions, equipment upgrades, or maintenance. Also, consider selecting different times across shifts to capture variations in productivity. This approach can help identify inefficiencies caused by timing, such as worker fatigue during late shifts or higher error rates at the end of the workday.

How to Perform Time Study Analysis: A Step-by-Step Guide

Performing a time study analysis may sound complex, but it’s actually not all that difficult, especially when it’s broken down into clearly defined steps. Here’s how to perform TSA properly:

- Define the Process You Want to Study: Step one is identifying the workflow you want to study and analyze. Specify clearly what the goal of the study is, and if it’s going to be a singular task or perhaps the entire workflow. Clarity here is much needed for the sake of staying focused.

- Break the Process Into Steps: Break down the process you have chosen into smaller, measurable steps. For example, if the focus of the study is how an employee assembles a gadget, the steps would be gathering tools, putting parts together, testing it, and cleaning up. Breaking it down makes it easier to see where time’s being spent.

- Gear up: You’re going to require tools that will make performing TSA possible. While it’s still perfectly okay to stick to the classic stopwatch, it’s best to make use of a video camera along with time-tracking software for more detailed tasks and accurate results.

- Select Candidates: Remember that the goal of this study is not to get the best numbers. As tempting as it might seem, this won’t give you results that are actually representative of your workforce’s capabilities. So, it’s best not to pick only the top performers. Rather, select a sample group of average workers, those stacked somewhere in the middle. Adequately trained workers should be the bulk of your sample, with a few outliers to get a truer picture.

- Inform the Candidates about TSA: For both ethical and practical reasons. Stay neutral, do not interfere with the workflow, and make sure the workers are comfortable. If employees know you’re not there to criticize, they’re more likely to work naturally, giving you reliable data.

- Collect Data: Observe each task and note down everything. Repeat this several times to account for variations in speed, interruptions, or other factors.

- Analyze the Data: Once data has been collected, analysis begins. Look for patterns and trends. Are there steps that consistently take too long? Is there a lot of back-and-forth movement or waiting? Use this data to establish a baseline time.

After collecting and analyzing the data, the next step is to put “improvement” strategies into action. This might involve offering better training to build skills, upgrading old equipment to improve efficiency, cutting out time-wasting tasks, or reorganizing the workspace for smoother operations.

How to Calculate Standard Time

Standard time is the average time it takes an employee, under normal working conditions and including breaks and delays, to complete a task. After gathering all the data, you can calculate it using these steps:

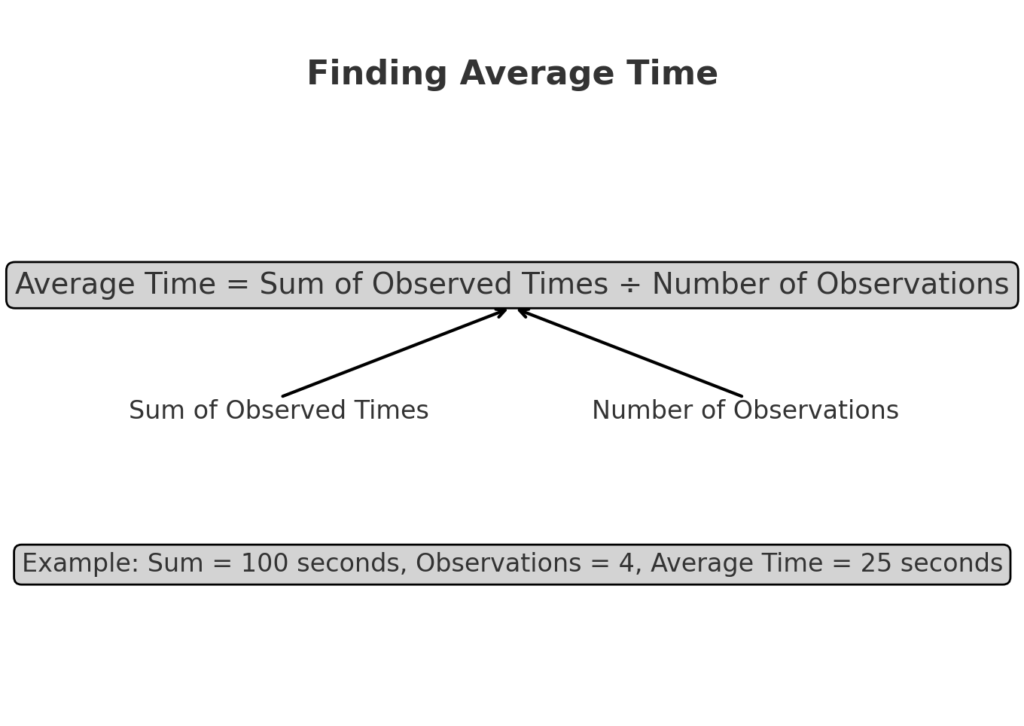

Step 1: Find Average Time

This is the (surprise!) average or mean time it takes for a trained employee to perform a task. It can be calculated using the formula:

| Average Time = Sum of Observed Times ÷ Number of Observations |

Step 2: Calculate Normal Time

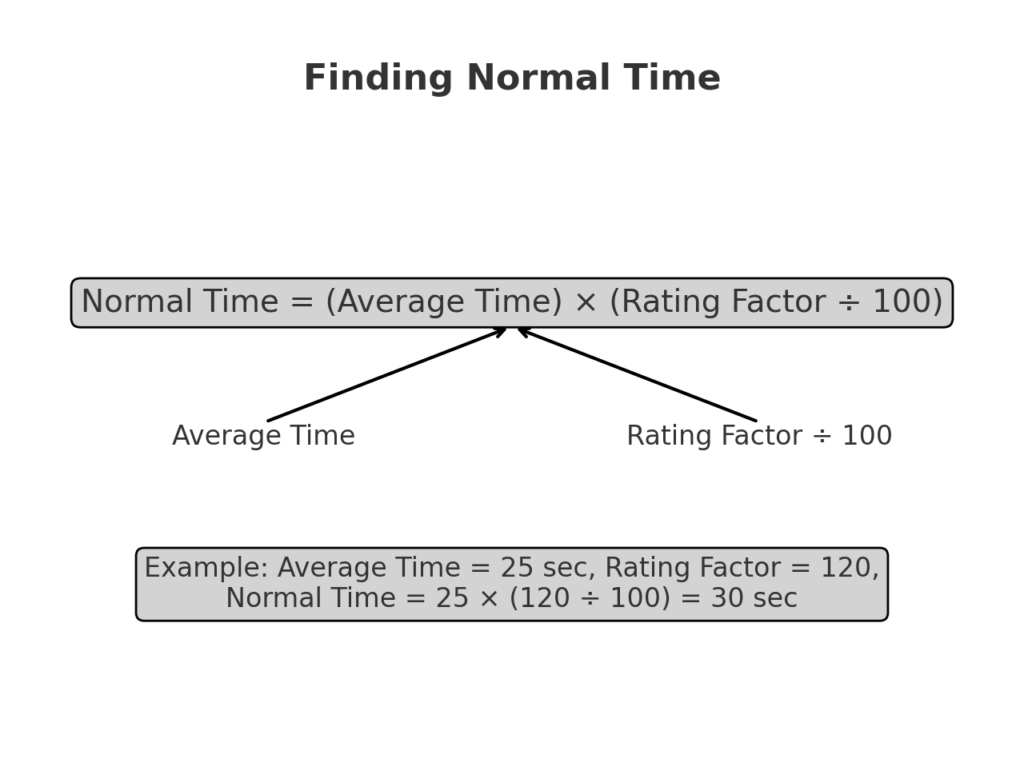

Normal Time is the time it takes to complete a task after adjusting for the worker’s performance. It can be found by multiplying the time (how long the task took) by the performance rating factor (how fast or slow the worker is working compared to an average worker). The formula for calculating normal time is:

| Normal Time = (Average Time) x (Rating Factor ÷ 100) |

Step 3: Account for Allowances

It’s unrealistic to expect employees to work round-the-clock. After all, even machines need breaks. The actual workflow of a production line would also include allowances, which can vary quite a bit from one company to another.

As a general rule of thumb, allowances include personal breaks (bathroom, rest, meals), health breaks (fatigue, mental or physical), and inevitable delays (machine maintenance, going from one place to another, changing equipment, startup, closing down). Accounting for allowances offers a more realistic total time for a task.

Step 4: Standard Time Calculations

To get the standard time, which is the time taken by a regular employee to perform a typical task under normal circumstances, taking into account allowances and interferences, use the formula:

| Standard Time = (Normal Time) x (1 + Allowances) |

Manufacturing Time Study Analysis Example

Let’s take the example of a manufacturing company that creates metal parts for cars. We’ll primarily focus on the specific part of creating car doors.

The task primarily includes 4 steps:

- Attach the door frame to the hinges

- Install the glass

- Fit the door handle

- Attach the inner lining

Step 1: Measure the Time for Each Step

For a thorough analysis, time a worker who performed a step multiple times (3, in this particular example) since the goal is to see how long each step takes on average.

- Attaching the door frame to the hinges: The worker took 2 minutes, 2.1 minutes, and 2.2 minutes in the three observations. The average time for this step is 2.1 minutes.

- Install the glass: The worker took 5 minutes, 5.2 minutes, and 5 minutes in the three observations. The average time for this step is 5.07 minutes.

- Fit the door handle: The worker took 1.5 minutes, 1.6 minutes, and 1.4 minutes in the three observations. The average time for this step is 1.5 minutes.

- Attach the inner lining: The worker took 3 minutes, 2.8 minutes, and 3.1 minutes in the three observations. The average time for this step is 2.97 minutes.

Step 2: Adjust for Performance (Normal Time)

Now, we adjust the average times to account for how the worker is performing. Let’s assume the worker is performing at a normal pace, so no adjustments are made (a performance rating of 1.0).

So, the normal time for each step is the same as the average time:

- Attach the door frame to the hinges: 2.1 minutes

- Install the glass: 5.07 minutes

- Fit the door handle: 1.5 minutes

- Attach the inner lining: 2.97 minutes

Step 3: Add Extra Time for Breaks (Allowance)

Now, we add extra time for things like breaks, setting up, or small delays. Let’s assume a 15% allowance for all tasks.

To calculate the standard time, we multiply the normal time by 1.15 (which represents the normal time plus the 15% allowance). Here’s how it works for each step:

- Attach the door frame to the hinges:

Normal time is 2.1 minutes.

Standard time = 2.1 × 1.15 = 2.415 minutes.

- Install the glass:

Normal time is 5.07 minutes.

Standard time = 5.07 × 1.15 = 5.83 minutes.

- Fit the door handle:

Normal time is 1.5 minutes.

Standard time = 1.5 × 1.15 = 1.725 minutes.

- Attach the inner lining:

Normal time is 2.97 minutes.

Standard time = 2.97 × 1.15 = 3.415 minutes.

Step 4: Results

Now we have the standard time for each step:

- Attach the door frame to the hinges: 2.415 minutes

- Install the glass: 5.83 minutes

- Fit the door handle: 1.725 minutes

- Attach the inner lining: 3.415 minutes

Step 5: Use the Data to Improve

Now that the company knows the standard times, they can use this data to improve the process. For example, installing the glass takes the most time (5.83 minutes). The company might consider:

- Automating the glass installation to speed up the process.

- Providing better training to the workers for more efficient techniques.

- Looking into faster tools or methods for the job.

Once the improvements are made, the company can conduct another time study to see if the standard times have decreased or not. This will help in improving them. Be sure to also learn how manufacturing solutions align with time study analysis insights.

How LLumin Can Optimize Operations

While paper, pen, stopwatch, and a keen eye are unmatched, it’s now possible to optimize asset usage and productivity with LLumin’s asset management platform. It’s designed to optimize operations, maintain assets, meet compliance requirements, and, in this particular case, help with time study analysis. Here are some of the many benefits you can enjoy while using our software:

- Track equipment performance in real-time. This is crucial for time study analysis because you can correlate equipment downtime or malfunctions with specific timeframes.

- Downtime, especially unplanned downtime, is the biggest perpetrator of delays in manufacturing. LLumin helps manage preventive maintenance schedules so equipment can get serviced before it breaks down. This directly impacts your time study analysis by reducing interruptions and providing more accurate data on task completion times.

- Time study analysis doesn’t just apply to workers’ tasks, but it can also be applied to maintenance activities. Using LLumin, maintenance tasks can be scheduled and monitored.

- Since LLumin is also available as a mobile app, you get real-time insights and alerts about your equipment, no matter where you are.

Schedule a demo with us today to see how your business can improve operational efficiency with preventive maintenance tools and time study analysis using LLumin.

Closing Thoughts

Combining time study analysis with a CMMS tool like LLumin can be a game-changer for your business. Why? Because TSA helps you measure and improve task efficiency, while a CMMS solution makes sure your equipment is running smoothly, reducing downtime. Together, they deliver real-time insights to identify inefficiencies and boost productivity.

Getting Started With LLumin

LLumin develops innovative CMMS software to manage and track assets for industrial plants, municipalities, utilities, fleets, and facilities. If you’d like to learn more about the total effective equipment performance KPI, we encourage you to schedule a free demo or contact the experts at LLumin to see how our CMMS+ software can help you reach maximum productivity and efficiency goals.

Take a Free TourFAQs

What are some examples of Time Study Analysis?

Examples of time study analysis include tracking the time it takes for a trained worker to complete a specific designated task. This can involve a variety of tasks, such as assembling a product, packaging it, or perhaps operating a machine. For example, in a factory, the time it takes to assemble a chair would be analyzed by TSA or, in an office setting, how long an employee takes to enter data.

What metrics should be tracked during a Time Study Analysis?

You’d ideally want to track key metrics like task completion time, idle time, setup time, and transition time between tasks. It’s also recommended to monitor factors that might influence employee performance, such as the condition of equipment, environmental factors, or worker fatigue.

What factors affect the accuracy of Time Study Analysis?

A lot of factors can mess up the results. For example, if an employee knows they’re being actively timed, they might work faster than usual. This is called the Hawthorne effect, a well-documented phenomenon where individuals alter their behavior because they know they are being observed. Other factors include observer bias, inconsistent task performance, uncooperative employees, or the use of improper tools. External conditions, such as faulty equipment or a change in work order, can also impact the results.

What are the challenges of conducting a Time Study Analysis?

There are various challenges faced when performing time study analysis, but the biggest hurdle is getting people on board. Employees may resist TSA because they might feel they are being micromanaged or judged, even though the end goal is to make things easier for everyone. Additionally, collecting consistent data is tricky business due to the unpredictable nature of work, along with the requirement for time and resources, such as trained observers and tools. This is especially difficult for small companies to tackle.

How does Time Study Analysis improve production efficiency?

Time study analysis helps shed light on unnecessary steps, delays, or repetitive tasks that are inefficient and time-consuming. Consider it a health check-up for your workflow. With the help of TSA, you can cut out wasted effort, establish clear benchmarks, have the entire production line run smoothly, and get more done in less time. Win-win!

Karen Rossi is a seasoned operations leader with over 30 years of experience empowering software development teams and managing corporate operations. With a track record of developing and maintaining comprehensive products and services, Karen runs company-wide operations and leads large-scale projects as COO of LLumin.