Transitioning to Condition-Based Maintenance with AI & Sensors

Calendar-based maintenance schedules treat every asset the same, servicing equipment whether it needs attention or not. This rigid approach wastes resources on unnecessary work while high-use assets wear out between scheduled intervals, creating exactly the failures that preventive maintenance claims to prevent.

By contrast, condition-based maintenance saves an average of 18% in annual maintenance spend by performing work only when data indicates emerging degradation. Yet many organizations remain locked in time-based routines that ignore actual equipment condition through smart maintenance scheduling disconnected from reality.

The transition to condition-based maintenance can be complicated, especially when doing it yourself. It requires the systematic integration of industrial IoT asset monitoring, AI-powered maintenance analytics, and work-order optimization that respond to equipment health rather than arbitrary intervals.

This article examines why calendar-based approaches fail, what condition-based maintenance actually entails, and how AI and sensors enable this strategy. We’ll also look at the practical steps required to prepare teams and systems for successful implementation through CMMS maintenance scheduling aligned with real-world asset behavior.

Why Calendar-Based Maintenance Isn’t Enough

Many teams still schedule maintenance based solely on time (e.g., lubricating pumps every 30 days, inspecting belts quarterly, replacing filters annually), regardless of the asset’s workload or operating conditions. This one-size-fits-all approach creates two simultaneous problems: underused assets receive unnecessary maintenance that wastes labor and materials, and high-use assets wear out early because they exceed design assumptions embedded in fixed schedules, with maintenance frequency reduced and disconnected from demand.

| Calendar-Based Limitation | Impact on Operations | Condition-Based Solution |

|---|---|---|

| Fixed intervals ignore workload | Overservice light-use assets, underservice heavy-use equipment | Usage triggers adjust to actual stress levels |

| No visibility into degradation | Failures occur between scheduled inspections | Real-time sensors detect emerging problems early |

| Resource waste on unecessary work | 15% of maintenance resources wasted (Artesis 2026) | Maintenance only when data indicates a need |

| Reactive to unexpected breakdowns | 82% experienced unplanned downtime in 3 years | Predictive maintenance automation prevents surprises |

Studies show most equipment failures are unrelated to age, yet time-based maintenance wrongly assumes that failures happen at regular, predictable intervals. A conveyor running light loads five days weekly doesn’t degrade at the same rate as one operating 24/7 at capacity, yet standard PM schedules service both identically. This creates a mismatch that either:

- Over-maintains the light-use asset

- Under-maintains the heavily loaded one through wear-based servicing, ignoring actual stress

Back to Basics: What Is Condition-Based Maintenance and Why Does It Matter?

Rather than usage hours or cycles, condition-based maintenance tracks actual asset condition to determine when service is genuinely required, using equipment performance data to reveal true health. Furthermore, these tools are customizable to include features such as CBM monitors, vibration signatures, temperature, and even acoustic emissions to detect actual bearing wear.

This approach is ideal for assets that wear out based on heavy use rather than age. For example:

- Pumps handling abrasive slurries

- Motors operating under variable loads

- Conveyors experiencing uneven stress

- Compressors subjected to extreme duty cycles

Common condition triggers include temperature changes indicating overheating or lubrication breakdown, and vibration anomalies revealing misalignment or bearing defects. Additional triggers include fluid contamination, suggesting seal failures, and pressure deviations, signaling flow restrictions or leaks, captured by industrial IoT asset monitoring and invisible to human observation.

| CBM Characteristic | How It Works | Maintenance Impact |

|---|---|---|

| Tracks actual condition | Monitors temperature, vibration, pressure, and fluid quality in real-time | Reveals degradation invisible to visual inspections |

| Ideal for wear-prone assets | Focuses on equipment experiencing variable loads and harsh conditions | Prevents failures on high-stress equipment |

| Multiple condition triggers | Temperature, vibration, pressure, contamination, and acoustic signals | Detects diverse failure modes early |

| Data-driven timing | Schedules work when thresholds approach, not on fixed calendars | 18% average maintenance cost reduction |

Plants adopting condition-based maintenance report a 20% increase in mean time between failures in the first year, demonstrating that aligning maintenance with actual equipment needs rather than arbitrary calendars improves reliability while reducing costs. The strategy transforms maintenance from reactive crisis response or wasteful calendar compliance into proactive intervention guided by data through downtime-prevention strategies rooted in evidence rather than assumption.

How AI and Sensors Make Condition-Based Maintenance Possible

The transition to condition-based maintenance becomes practical only when organizations combine certain technological capabilities:

- Real-time sensor networks capturing equipment health indicators

- AI algorithms are refining condition thresholds and predicting failures

- Automated work order generation responding to emerging issues through sensor-driven maintenance, eliminating manual monitoring gaps

The following subsections outline these capabilities, explaining how they work, the conditions that need to be met for them to function as advertised, and how they contribute to a high-functioning maintenance model.

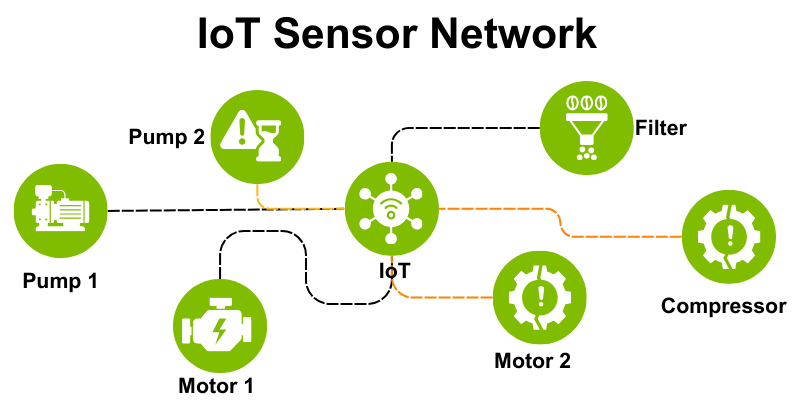

Monitoring Real-Time Asset Condition with IoT Sensors

Sensors continuously track temperature, vibration, pressure, acoustic emissions, and other indicators of asset health, rather than during periodic inspections that miss degradation between visits, through industrial IoT asset monitoring, providing 24/7 visibility. IoT-enabled maintenance can slash unplanned downtime by up to 35% while boosting overall equipment effectiveness 15-20%, demonstrating how continuous monitoring transforms maintenance intelligence.

Real-time condition data flows into your CMMS to inform smarter service decisions, enabling consistent, condition-led maintenance across all teams and locations through standardized, enterprise-wide equipment performance tracking. Tri-axial accelerometers detect bearing defects weeks before failure, thermocouples detect overheating immediately, pressure transducers identify pump cavitation, and ultrasonic sensors detect compressed-air leaks invisible to the human ear.

These capabilities are effectively impossible on a calendar-based system. Manufacturers deploying smart sensors report a 30% reduction in emergency maintenance spend, cutting the premium costs associated with rush part orders, overtime labor, and production disruptions caused by reactive maintenance, through maintenance cost reduction enabled by proactive visibility.

AI-Driven Thresholds and Optimization

AI can analyze historical performance to refine condition-based schedules beyond simple threshold alerts, learning what “normal” looks like for each asset under varying operating conditions through predictive maintenance automation that adapts continuously. Gradient boosting and recurrent neural networks achieve 92% prediction accuracy for rotating-asset failures by ingesting sensor data, operational parameters, and contextual variables like ambient temperature and load profiles.

Real-Time Alerts and Automated Work Order Generation

Maintenance tasks are automatically triggered as thresholds approach, eliminating manual monitoring and ensuring timely response through work order optimization, removing human delay. AI forecasts future service needs based on condition trends and early warning signs, allowing planners to schedule work during low-production windows rather than reacting to emergency failures through smart maintenance scheduling aligned with operations.

As work orders are generated, technicians receive timely alerts with complete context, including:

- Trend charts

- Recommended action

- Parts lists

- Procedures

Each one is improving planning and reducing reactive work by using CMMS maintenance scheduling, providing all the information needed for efficient execution. Plants using automated work-order generation report 40% faster response times than manual entry, demonstrating how automation accelerates maintenance response times.

Preparing Your Team and Systems for the Transition

Successful condition-based maintenance implementation requires more than technology; it demands careful asset selection, clean data foundations, and workforce preparation that transform how teams approach maintenance decisions through change management supporting adoption.

Identify the Right Assets for Condition-Based Maintenance

Not every asset needs condition-based triggers, so focus on wear-prone or condition-sensitive equipment where CBM delivers the highest value through prioritized deployment. Balance workload criticality, failure modes, and historical data availability when selecting candidates—high-criticality rotating equipment, assets with expensive downtime costs, and machines experiencing variable loads top most lists through asset criticality analysis, guiding investment.

Start with a pilot group before scaling across the facility, learning lessons on a manageable scope that informs broader deployment through phased implementation, reducing risk. Plants using combined vibration-temperature analytics report 45% fewer catastrophic gearbox failures, demonstrating the value of targeting high-impact assets first.

Clean Up Asset and Usage Data

You can’t improve what you can’t measure. Ensure sensors and data inputs are reliable before expecting accurate predictions through data quality foundations supporting analytics. Eliminate duplicate asset IDs, unify metrics across sites, and standardize input formats so algorithms train on consistent, accurate information through master data management, enabling AI effectiveness.

Clean data provides the foundation for automated scheduling by ensuring condition signals accurately reflect equipment health rather than instrumentation noise or inconsistent recording practices, through maintenance data analytics that require quality inputs. Data governance councils cut audit preparation time by 60% while meeting compliance requirements, demonstrating the broader value of systematic data management.

Train Maintenance Teams for Your New Scheduling

Technicians need clarity on how and why condition-based scheduling works to support buy-in and act efficiently when alerts arrive through workforce enablement, building confidence. Dashboards, alerts, and threshold visibility keep teams informed and engaged, providing transparency into the logic behind maintenance recommendations through digital literacy development supporting adoption.

| Training Component | What Technicians Learn | How It Supports CBM Adoption | Business Impact |

|---|---|---|---|

| Condition-based fundamentals | Why equipment condition determines service timing | Builds understanding and buy-in for the new approach | Reduces resistance to workflow changes |

| Dashboard navigation and interpretation | How to read asset health information via the dashboard | Enables independent data access without IT | Technicians respond faster to emerging issues |

| Alert prioritization and response | Distinguishing critical and routine notifications | Prevents alert fatigue, ensures timely response | 63% higher tool adoption with 20+ training hours |

| Threshold logic and trigger points | Understanding how AI sets dynamic thresholds | Provides transparency into recommendations | Increases confidence in automated scheduling |

| Real-time coordination | Using condition forecasts to plan interventions | Minimizes operational disruption | Replaces emergency responses |

Real-time condition data helps planners coordinate service with minimal disruption by showing exactly when equipment will reach critical thresholds. This allows for scheduled interventions during low-production periods rather than emergency responses, thereby improving operations through maintenance planning optimization. Facilities investing 20 training hours per technician achieved 63% higher tool adoption, demonstrating the value of workforce preparation.

LLumin CMMS+ Gives You Full Control Over Condition-Based Scheduling

LLumin integrates with sensors, PLCs, and other control systems to track asset usage in real time, providing the data foundation that condition-based maintenance requires through CMMS integration with telematics connecting equipment to analytics. Users can define condition thresholds based on:

- Vibration levels

- Temperature ranges

- Fluid metrics

- Real-time sensor inputs

Smart rules and automated workflows ensure the right task is triggered at the right time, eliminating manual monitoring while providing complete audit trails for compliance through work order optimization, streamlining execution. Teams get visibility into upcoming usage thresholds and historical performance for better planning, enabling proactive resource allocation rather than reactive scrambling through predictive maintenance automation supporting strategic decisions.

Book a Demo to See Condition-Based Maintenance in Action

AI and sensor integrations make your maintenance strategy smarter and more targeted by aligning work with actual equipment needs rather than arbitrary calendars, eliminating guesswork. LLumin CMMS+ turns usage data into automated scheduling, helping you reduce costs and improve uptime through digital transformation in maintenance and modernized operations.

Book a free demo today to see how you can transition to condition-based maintenance that transforms your operations from a cost center to a strategic advantage through smart maintenance scheduling, delivering competitive differentiation.

Frequently Asked Questions

What types of assets benefit most from condition-based maintenance?

Condition-based maintenance delivers the highest value for rotating equipment experiencing variable loads (pumps, motors, compressors), wear-prone assets in harsh environments (conveyors handling abrasives, gearboxes under continuous stress), and high-criticality machines where failures cause expensive downtime. Focus CBM investment on assets where degradation patterns are detectable through sensors and where failure costs justify monitoring infrastructure.

How is condition-based different from use-based maintenance?

Use-based maintenance triggers work after specific operating hours or cycle counts, while condition-based maintenance responds to actual equipment health indicators like vibration, temperature, or fluid quality. Use-based assumes consistent wear rates; condition-based adapts to actual degradation regardless of runtime. Many organizations blend both—using cycle counters for consumables and condition sensors for critical rotating assets.

How do sensors connect to LLumin CMMS+?

LLumin integrates with sensor networks through standard industrial protocols (OPC-UA, MQTT, Modbus) and IoT platforms, enabling real-time data flow from edge gateways or cloud analytics services. APIs push condition alerts and health scores directly into CMMS work-order queues, while bidirectional sync returns completion data for algorithm retraining, creating a closed-loop improvement without manual data entry.

Can we combine condition-based triggers with preventive schedules?

Yes, LLumin supports hybrid strategies in which calendar-based PM handles routine tasks (filter changes, inspections), while condition-based triggers manage critical components. This approach maintains compliance with time-based regulatory requirements while optimizing high-value assets through sensor intelligence. The system automatically coordinates both trigger types to prevent scheduling conflicts.

How does AI improve condition-based maintenance accuracy?

AI analyzes historical sensor data, failure events, and operating contexts to learn what “normal” looks like for each asset under varying conditions. Machine learning models detect subtle degradation patterns weeks before simple threshold alerts would trigger, reducing false positives while catching genuine problems earlier. Plants deploying AI-driven CBM achieve 92% prediction accuracy, dramatically improving maintenance timing precision.

Ed Garibian, founder, and CEO of LLumin Inc., is an experienced executive and entrepreneur with demonstrated success building award-winning, growth-focused software companies. He has an impressive track record with enterprise software and entrepreneurship and is an innovator in machine maintenance, asset management, and IoT technologies.