Condition-Based vs Use-Based Preventive Maintenance: Which Works Best?

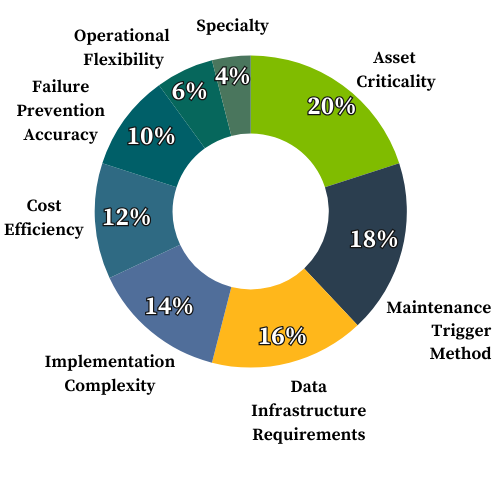

In September 2025, our research team conducted a comprehensive study of maintenance approaches used across 73 industrial facilities in North America. We analyzed these maintenance strategies using the following factors:

- Asset Criticality: Impact of asset failure on operations

- Maintenance Trigger Method: How maintenance timing is determined

- Data Infrastructure Requirements: Technology and instrumentation needed

- Implementation Complexity: Ease of deployment and management

- Cost Efficiency: Initial investment versus long-term savings

- Failure Prevention Accuracy: Ability to predict and prevent failures

- Operational Flexibility: Adaptability to changing conditions

- Specialty: Optimal use case scenario.

Based on this weighted algorithm, we have provided a detailed comparison between maintenance approaches to help teams select the right strategy for their assets. The table below shows the top performers across key criteria, with detailed analysis following each profile.

| Condition-Based Maintenance | Used-Based Preventive Maintenance | |

|---|---|---|

| Trigger Method | Real-time sensor data | Runtime hours/cycles |

| Data Requirements | IIoT sensors, SCADA, PLCs | Basic counters or meters |

| Implementation Complexity | High | Low |

| Specialty | Proactive health monitoring | Scheduled interval tasks |

| Best For | Critical, variable-load assets | Predictable-wear equipment |

The following sections provide a more in-depth analysis of condition-based vs use-based preventive maintenance.

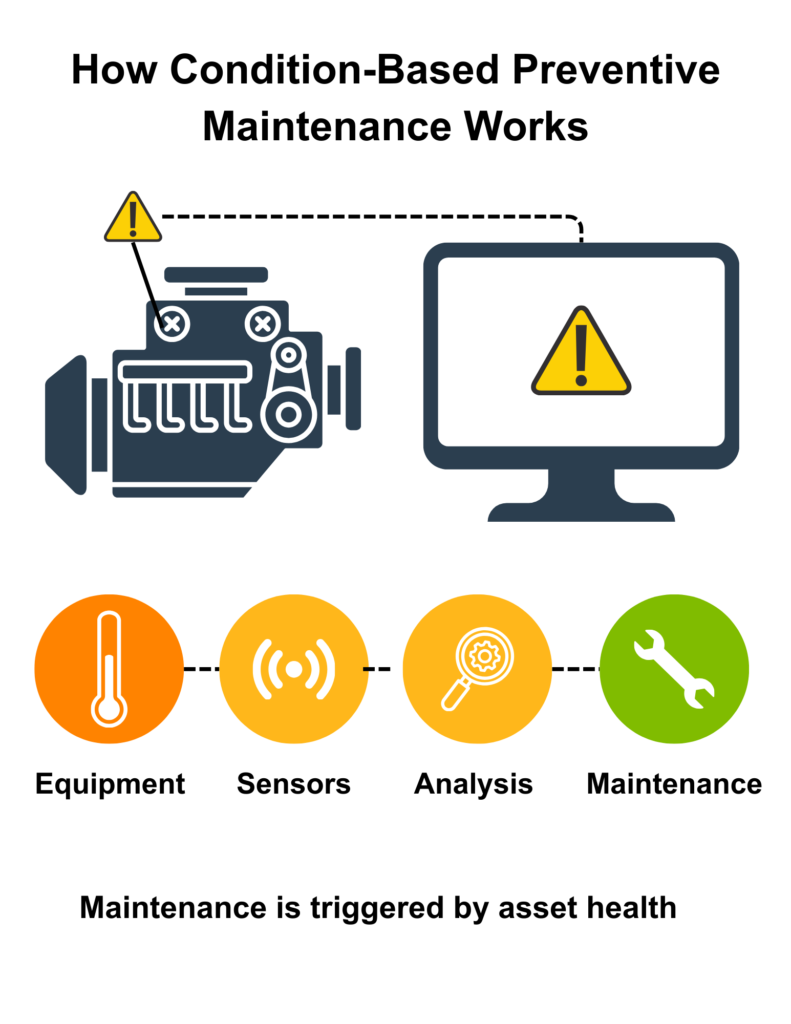

Condition-Based Maintenance: For Real-Time Asset Health Monitoring

Condition-based maintenance transforms how teams approach asset care by triggering work orders only when equipment shows early signs of wear or abnormal behavior. Rather than relying on estimates or fixed schedules, maintenance occurs based on actual asset health indicators captured through vibration analysis, temperature monitoring, load tracking, and other performance metrics.

This approach leverages IIoT maintenance alerts, SCADA and PLC data, and sensor-based monitoring to detect emerging issues before they escalate into failures. Teams act on condition changes rather than assumptions, which means servicing happens at precisely the right moment—after wear begins but before breakdown occurs.

Why It Works

Condition-based maintenance excels at protecting high-value or high-risk assets where unplanned downtime carries significant financial or safety consequences. Equipment operating under variable loads or unpredictable environments benefits most from this strategy because:

- Fixed intervals often miss abnormal wear patterns

- It detects problems early through continuous monitoring

- It makes maintenance workloads more targeted and efficient

Organizations implementing condition-based maintenance report reducing maintenance costs by 8-12% compared to traditional preventive approaches while extending equipment lifespan by 20-40%. By detecting problems early through continuous monitoring, teams reduce the risk of unexpected failures and avoid unnecessary servicing that wastes both labor hours and components.

The maintenance workload becomes more targeted and efficient. Rather than servicing all assets on the same schedule, regardless of their actual condition, technicians focus their efforts where data indicates a genuine need. This data-driven maintenance approach improves reliability for assets with inconsistent operating patterns and helps teams make informed decisions about repair timing.

What it Requires

Implementing condition-based maintenance demands:

- Reliable data streams from sensors

- Integrations with existing systems

- Personnel capable of interpreting asset health indicators.

It should also be noted that the upfront investment in instrumentation and configuration is notably higher than that of simpler preventive approaches, and the ongoing complexity of maintaining data dependencies requires specialized technical expertise.

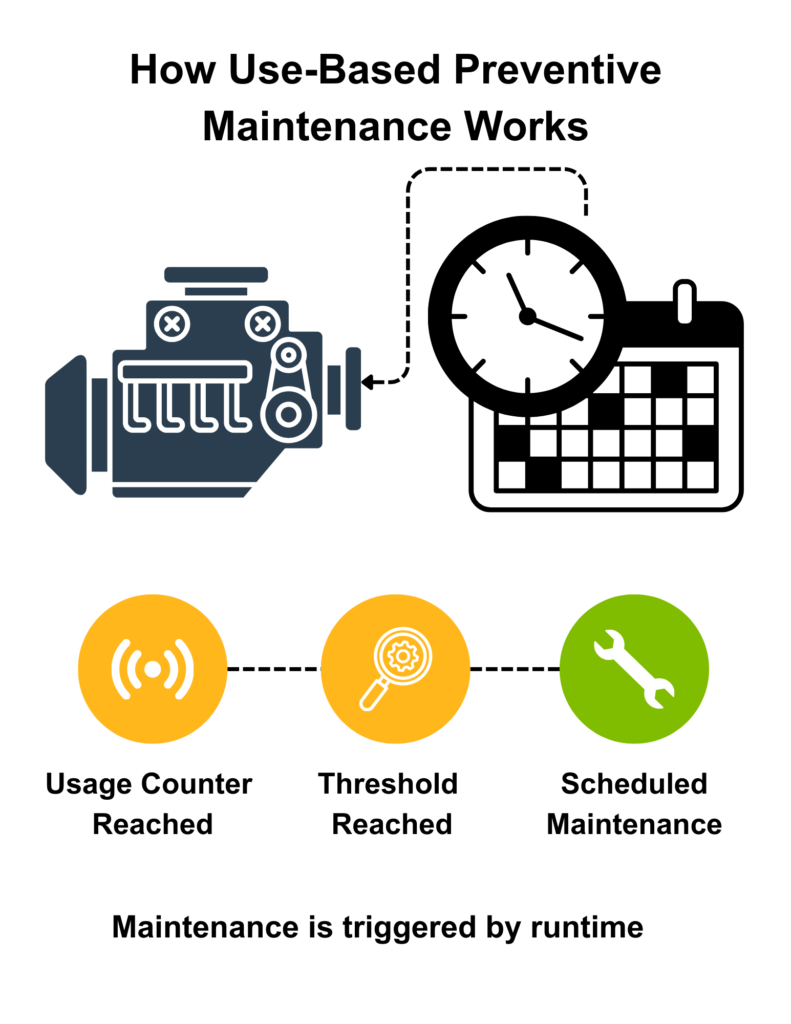

Use-Based Preventive Maintenance for Predictable Maintenance Intervals

Use-based preventive maintenance triggers tasks after the equipment reaches a defined number of operating hours, production cycles, batches processed, or when the equipment starts. This method relies on predictable wear patterns, initiating maintenance when runtime meters or cycle counters hit predetermined thresholds rather than waiting for calendar dates.

The approach provides stable, repeatable maintenance intervals that teams can plan weeks or months in advance. Maintenance schedules remain consistent and easy to follow because tasks occur at the same usage milestones regardless of calendar time, making resource allocation and labor planning more predictable.

Why it Works

Use-based maintenance works exceptionally well for assets with consistent duty cycles and predictable component wear. Equipment running in stable environments with steady operational patterns generates reliable data on when service is genuinely needed based on actual use rather than arbitrary dates.

Studies show that organizations adopting use-based preventive maintenance reduce spare parts inventory costs by 15-20% through better planning and avoiding emergency procurement. The simplicity of implementation means teams require minimal instrumentation or data infrastructure (often just basic runtime meters), making this approach accessible even without sophisticated monitoring systems.

Lower-risk assets that don’t justify investment in condition monitoring sensors benefit most from use-based schedules. The method supports stable labor planning because technicians know exactly when maintenance will be required, allowing for efficient scheduling and consistent execution of repetitive tasks.

What it Requires

The primary limitation of use-based maintenance is that it doesn’t account for abnormal wear or unexpected operating conditions. This makes it easier to implement, but also means that equipment experiencing unusual stress or contamination may fail before reaching its scheduled service interval. Similarly, it may mean that under-utilized assets may receive unnecessary servicing when usage-based thresholds arrive sooner than actual wear requires.

What use-based maintenance saves in the short-term, then, gets paid back in full over time; long-term costs can escalate if maintenance intervals don’t align with actual asset behavior patterns. Without visibility into real-time equipment condition, teams may either over-maintain assets (wasting labor and materials) or miss early failure warnings that condition monitoring would catch.

How To Decide Between Condition-Based Vs Use-Based Preventive Maintenance Approaches

Because both condition-based vs use-based preventive maintenance approaches have their respective use cases, it’s important to understand how to apply them to your operations. The following subsections provide some basic insight to help readers determine the best method for them.

Consider Asset Criticality

Critical equipment that directly impacts production output, worker safety, or regulatory compliance warrants the investment in condition-based monitoring. Assets whose failure creates significant downtime costs (sometimes exceeding $125,000 per hour in manufacturing) justify the higher initial expense of sensors and data infrastructure.

Lower-impact assets that support rather than drive operations can follow predictable use-based schedules without risking severe operational consequences.

| Select Condition-Based Maintenance If… | Select Use-Based Maintenance If… |

|---|---|

| – Asset failure impacts production output, safety, or compliance – Downtime costs exceed $100,000+ per hour – Equipment is mission-critical to operations | – Asset supports but doesn’t drive core operations – Failure consequences are manageable – Equipment has backup redundancy |

Evaluate Failure Behavior Patterns

Equipment exhibiting variable wear due to changing loads, environmental factors, or duty cycles favors condition-based approaches. When operating conditions fluctuate significantly, fixed usage intervals often prove too rigid to prevent failures or too conservative, resulting in over-maintenance.

Assets with consistent, predictable wear profiles, where historical data shows reliable correlation between usage and component degradation, are best suited for use-based maintenance intervals.

| Select Use-Based Maintenance If… | Select Use-Based Maintenance If… |

|---|---|

| – Equipment experiences variable loads or duty cycles – Operating conditions fluctuate significantly – Wear patterns are unpredictable or environment-dependent | – Equipment runs consistent, predictable duty cycles – Historical data shows a reliable usage-to-wear correlation – Operating environment remains stable |

Assess Data Availability and Infrastructure

Condition-based maintenance requires reliable sensor inputs, system integrations, and personnel capable of interpreting asset health data. Organizations lacking this foundation should consider building infrastructure on critical assets first while maintaining use-based schedules elsewhere.

Use-based approaches work effectively when only runtime data or cycle counters are available. This makes the strategy accessible to teams without extensive condition monitoring infrastructure.

| Select Condition-Based Maintenance If… | Select Use-Based Maintenance If… |

|---|---|

| – Sensors and monitoring systems are already in place – The team has data analysis capabilities – Integration with SCADA/PLC systems exists | – Only basic runtime meters or counters are available – Limited monitoring infrastructure exists – Team lacks advanced analytics expertise |

Analyze Cost Considerations

Condition-based maintenance reduces unnecessary labor and extends asset life, but it requires an upfront investment in instrumentation. The U.S. Department of Energy reports that predictive maintenance approaches save 8-12% over preventive maintenance and up to 40% over reactive strategies.

Use-based maintenance is inexpensive to initiate, requiring minimal technology. However, long-term efficiency may suffer if intervals don’t match actual equipment behavior, potentially leading to higher total maintenance costs through either over-servicing or missed early warnings.

| Select Condition-Based Maintenance If… | Select Use-Based Maintenance If… |

|---|---|

| – ROI justifies upfront sensor investment – Preventing a single failure saves more than the implementation cost – Long-term cost reduction is a priority | – Budget constraints limit technology investment – Quick implementation is needed – Maintenance costs are already manageable |

Gauge Operational Maturity

Teams with advanced monitoring capabilities, skilled analysts, and mature data governance can implement condition-based maintenance more rapidly and effectively. Organizations earlier in their maintenance journey often benefit from starting with use-based schedules while building capability for more sophisticated approaches.

Research indicates that 88% of manufacturing companies use preventive maintenance, with 40% also employing predictive and condition-based methods using analytics tools. This hybrid approach reflects the practical reality that different asset classes warrant different strategies.

| Select Condition-Based Maintenance If… | Select Use-Based Maintenance If… |

|---|---|

| – The organization has advanced monitoring capabilities – Skilled data analysts are available – Mature maintenance processes exist | – Team is building maintenance program foundations – Limited technical expertise is available – Focus is on establishing consistent preventive routines |

How to Implement an Effective Combined Approach

A hybrid maintenance model applies each method to assets that best suit it. This balanced strategy reduces the risk of failure while avoiding unnecessary preventive maintenance and keeping maintenance workloads manageable. There are a few ways to implement this hybrid approach:

- Critical assets with variable operating conditions receive continuous condition monitoring, while stable equipment follows use-based maintenance intervals.

- Some organizations implement a tiered approach, where the most critical 20% of assets receive condition-based monitoring, the next 50% follow use-based schedules, and the remaining lower-risk assets operate on time-based or run-to-failure strategies.

The combined strategy works best when teams regularly review asset behavior and adjust maintenance intervals or monitoring thresholds in response to changing operating conditions. Analysis of work order data, failure patterns, and asset performance should drive continuous optimization of maintenance schedules across all equipment classes.

Organizations that adopt proactive maintenance strategies report 52.7% less unplanned downtime compared to those that use reactive approaches. The key is matching the maintenance strategy to the asset’s criticality, failure patterns, and available data infrastructure, rather than applying a single method universally.

How LLumin CMMS+ Supports Both Preventive Maintenance Methods

LLumin CMMS+ unifies runtime counters, sensor inputs, and inspection data in a single scheduling engine that handles both condition-based and use-based maintenance triggers. The platform enables teams to configure maintenance intervals based on operating hours, production cycles, or real-time condition thresholds.

Teams using LLumin can integrate SCADA and PLC data alongside meter readings to create a comprehensive view of asset health. The system automatically generates work orders when either usage thresholds or condition alerts are triggered, ensuring maintenance occurs at optimal timing regardless of which strategy applies to each asset.

Mobile CMMS capabilities allow technicians to capture real-time data during inspections, feeding continuous improvement of maintenance planning. OEE monitoring and comprehensive reporting help teams analyze actual equipment behavior, refine intervals, and optimize the balance between preventive and condition-based approaches.

The platform supports long-term maintenance optimization by tracking performance trends, correlating maintenance actions with asset reliability outcomes, and providing visibility into which strategies deliver the strongest results for different equipment classes. Learn more about condition-based maintenance implementation with LLumin.

Build an Adaptable Preventive Maintenance Strategy with LLumin

Both condition-based and use-based preventive maintenance offer distinct advantages, depending on the asset’s behavior and operational environment. Condition-based approaches excel at protecting critical, variable-load equipment through real-time monitoring, while use-based methods provide reliable, predictable schedules for stable-duty-cycle assets.

The most effective maintenance programs intelligently combine both strategies, applying each where it delivers maximum value. LLumin CMMS+ helps teams implement hybrid preventive maintenance strategies that improve equipment reliability while reducing unnecessary maintenance workload.

Book a demo to see how LLumin CMMS+ supports condition-based vs use-based preventive maintenance as well as hybrid preventive maintenance strategies that drive failure risk reduction and maintenance optimization across your facility.

Frequently asked questions

What is the difference between condition-based and use-based maintenance?

Use-based maintenance triggers tasks after equipment reaches a defined number of operating hours, cycles, or starts, relying on predictable wear patterns. Condition-based maintenance uses real-time sensor data, including vibration, temperature, and load, to trigger maintenance only when equipment shows early signs of abnormal behavior or wear. Use-based follows fixed thresholds; condition-based responds to the actual health of the asset.

When is condition-based maintenance the better option?

Condition-based maintenance is most effective for critical, high-value assets where unplanned downtime incurs a significant cost or poses a safety risk. Equipment with variable operating loads, unpredictable duty cycles, or harsh environmental conditions benefits most because fixed intervals often miss abnormal wear patterns. Assets where failure prediction delivers measurable ROI justify the higher investment in sensors and data infrastructure.

Do teams need sensors to begin condition-based maintenance?

Yes, condition-based maintenance requires reliable data inputs from IIoT sensors, SCADA systems, PLCs, or other monitoring devices that track asset health indicators, such as vibration, temperature, pressure, or load. However, teams can start with manual condition monitoring using handheld devices on critical assets before investing in continuous automated monitoring. The key is establishing consistent data collection and analysis processes that inform maintenance timing decisions.

How can organizations combine both maintenance strategies?

Organizations implement hybrid models by applying condition-based monitoring to critical assets with variable loads and use-based schedules to predictable, lower-risk equipment. A typical approach places the most critical 20-30% of assets under continuous condition monitoring while maintaining the remaining equipment on use-based or time-based intervals. Regular analysis of failure patterns and maintenance costs helps teams continuously optimize which strategy applies to each asset class.

How does a CMMS help refine preventive maintenance intervals?

A CMMS tracks work order history, failure patterns, and actual equipment runtime to reveal whether maintenance intervals are too frequent or too conservative. By correlating maintenance actions with asset performance outcomes, teams identify opportunities to extend intervals on over-maintained assets or increase monitoring on equipment experiencing frequent failures. The system provides visibility into maintenance workload control, helping to balance preventive tasks with reactive demands for optimal resource allocation.